01.What is a porous aluminum plate?

Porous plates are based on the principle of porous structure bionics

Develop new high-strength environmentally friendly building composite materials

The reason why it is called porous plates

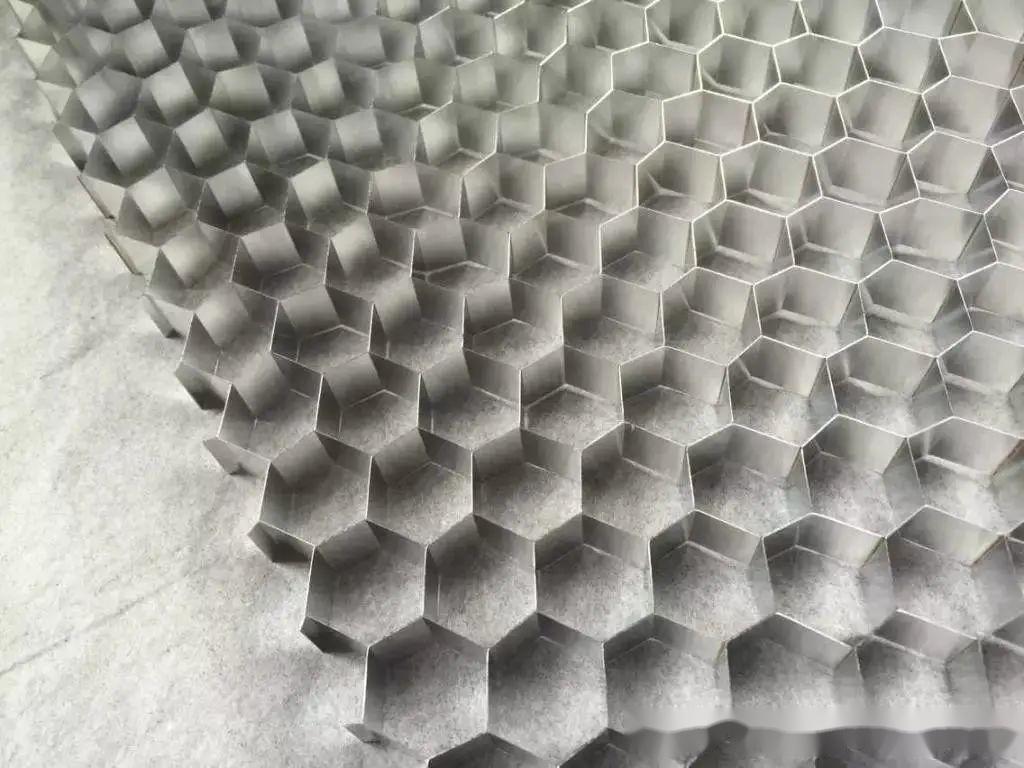

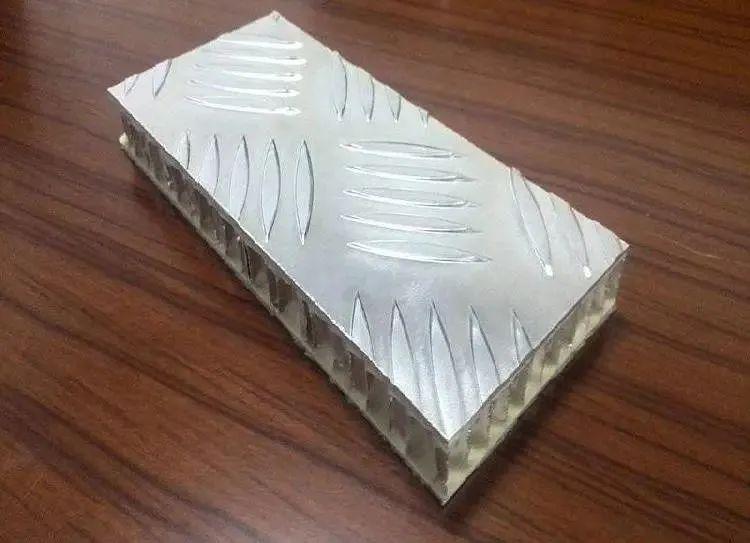

Because it is made of honeycomb core as the substrate

△Aluminum honeycomb core layer

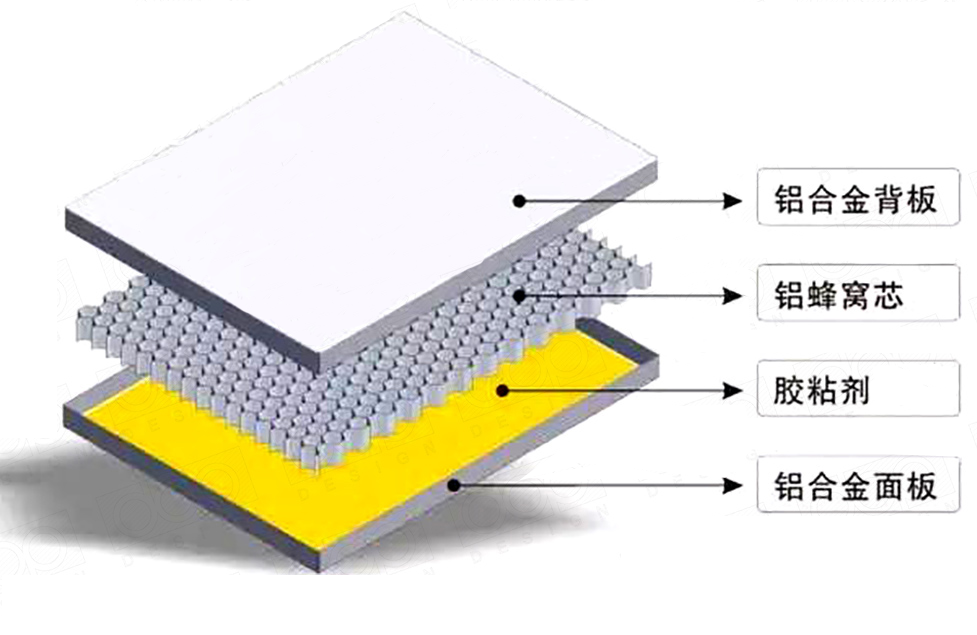

Aluminum honeycomb panels are a series of metal composite panels developed in combination with aviation industry composite honeycomb panel technology. They use a “honeycomb sandwich” structure, which is a composite panel made of high-strength alloy aluminum panels with a decorative coating with excellent weather resistance as the surface and bottom plate and aluminum honeycomb core through high temperature and high pressure.

Schematic diagram

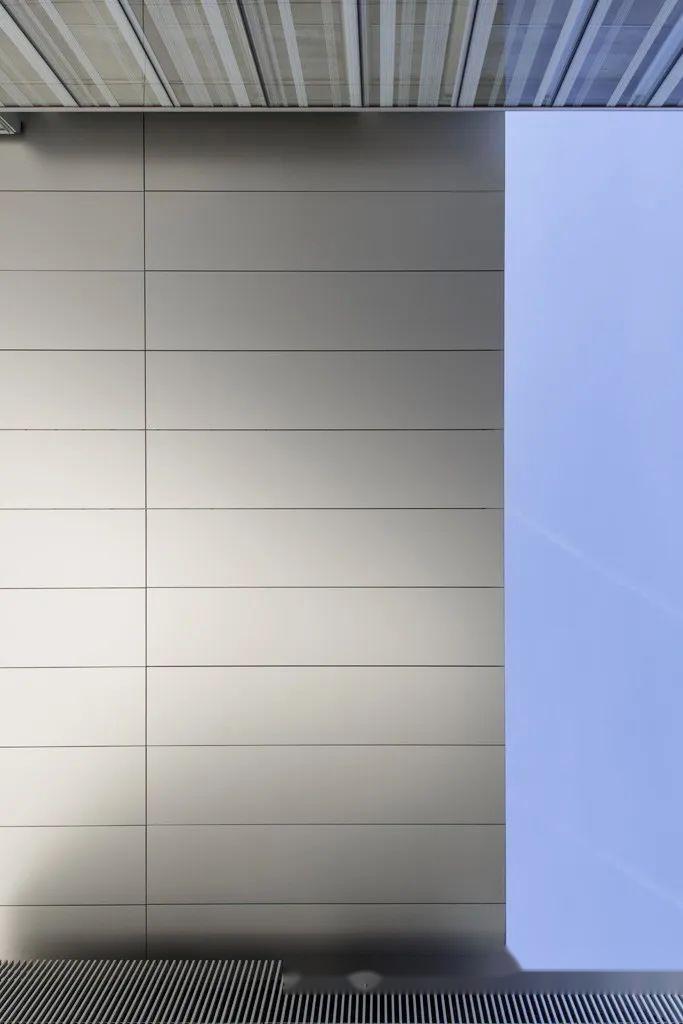

This type of sheet material will greatly enhance the structural integrity of the original aluminum sheet, making it less prone to bending, allowing for a larger scale and better flatness.

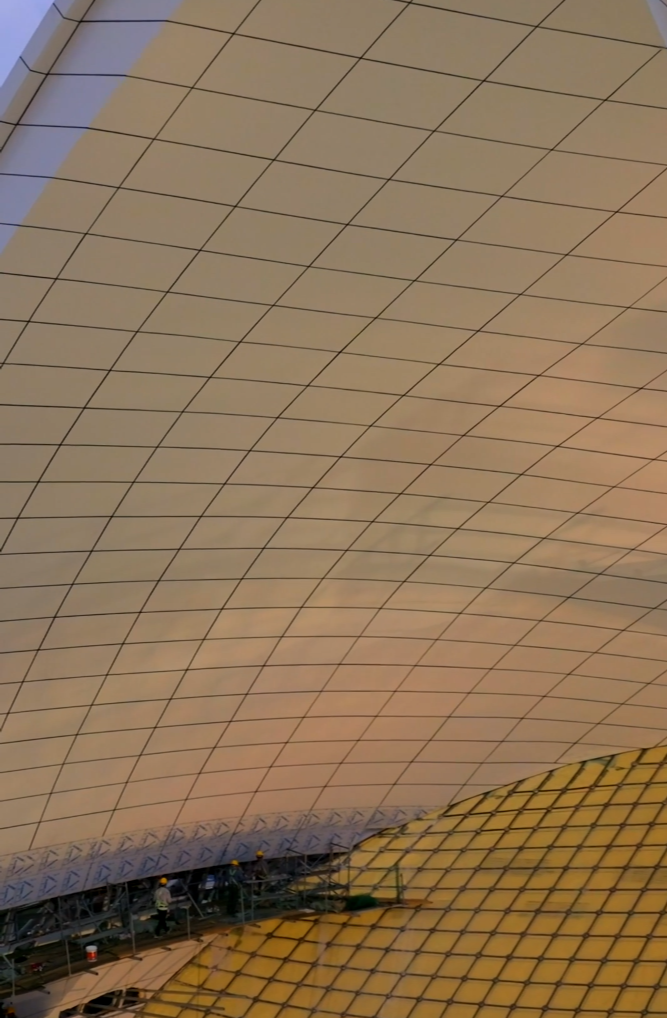

Jacobin Cultural Plaza ceiling application

「Performance characteristics」

①Large panel, high flatness: No reinforcement measures are required, the panel size of the honeycomb aluminum panel can reach 1500*5000mm, and it can maintain excellent flatness.

②Light weight: The weight of the honeycomb aluminum panel is only 5~5.5kg/square meter, which greatly reduces the load-bearing load of the building.

③High strength: It can withstand high-intensity pressure and shear force, is not easy to deform, and can meet the requirements of wind pressure resistance of super high-rise buildings.

④Product customization: Honeycomb aluminum panels can be tailored according to customer needs in terms of size, shape, paint and color.

⑤Easy installation: It can be installed in any order, and each wall panel can be disassembled and replaced separately, which improves the flexibility of installation and maintenance and reduces costs.

⑥Box structure: The honeycomb aluminum panel is a box structure with edges on all sides, which has good airtightness and improves the safety and service life of the honeycomb aluminum panel.

⑦ No welding and no exposed nails: When installing the base layer and surface layer of the honeycomb aluminum panel, angle codes and screws are used to connect them, eliminating the need for frame welding, and there are no exposed nails on site after the surface layer is installed, making it clean and tidy.

Real-life pictures

「6 common aluminum honeycomb panel materials」

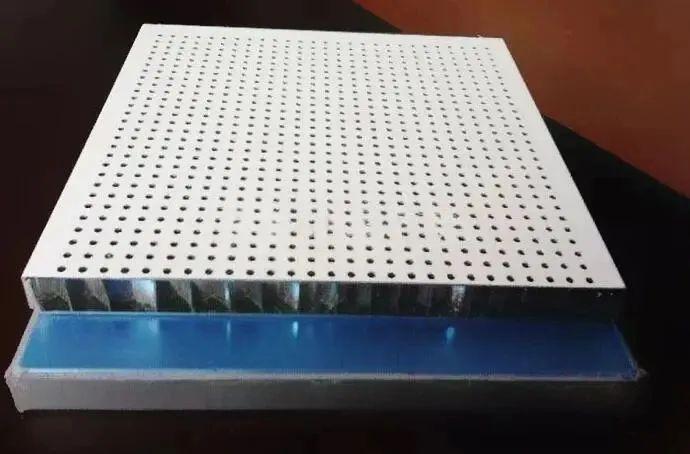

① Punched honeycomb aluminum panel

Punched honeycomb aluminum panel is a kind of metal decorative panel that uses CNC punching equipment to make holes of various shapes on the surface of the honeycomb aluminum panel. Various fillers can be added according to various special needs.

② Carved honeycomb aluminum plate

Carved aluminum plate is a kind of honeycomb aluminum plate with various artistic patterns carved by engraving machine. By combining different patterns with different environments, it breaks through the traditional modeling concept and makes the aluminum carved lines brighter and more elegant.

③ Imitation wood grain honeycomb aluminum plate

Imitation wood grain honeycomb aluminum plate is a natural wood grain effect made by powder treatment on the surface of aluminum plate, with realistic color and texture, and firm and wear-resistant pattern.

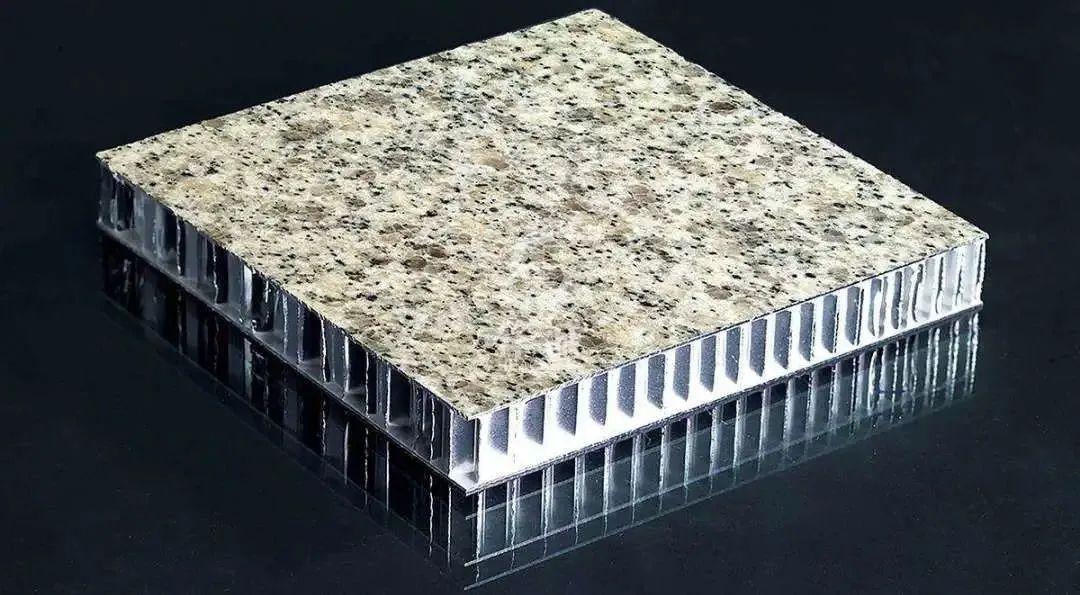

④ Stone-like honeycomb aluminum plate

Stone-like honeycomb aluminum plate is a new type of decorative material that is based on aluminum plate and processed through a special spraying process to give the honeycomb aluminum plate a strong three-dimensional sense of stone.

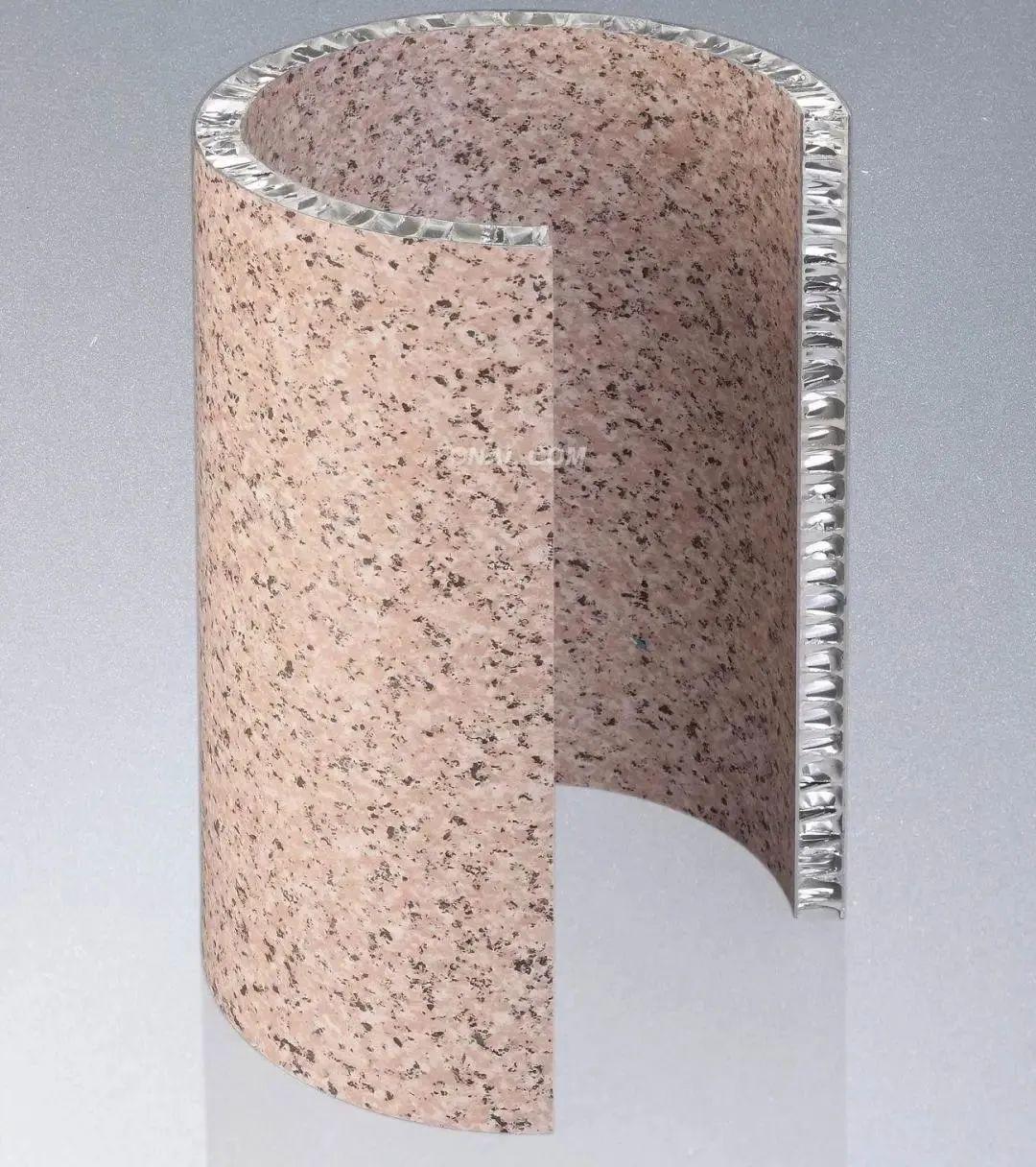

⑤ Arc-shaped and special-shaped honeycomb aluminum panels

Arm-shaped and special-shaped honeycomb aluminum panels are made into round honeycomb aluminum panels, conical honeycomb aluminum panels, arc-shaped honeycomb aluminum panels and other shapes according to customized requirements. Shaped honeycomb aluminum panels are a kind of metal decorative material with strong decorative and aesthetic properties.

‘

⑥ Fluorocarbon honeycomb aluminum plate

The surface coating of fluorocarbon honeycomb aluminum plate is customized according to the needs, and the process can be divided into fluorocarbon spraying, powder spraying, and fluorocarbon pre-roller coating. Among them, the fluorocarbon spraying surface coating can be divided into two coatings and three coatings according to the processing technology, and the powder spraying surface coating is one coating and one baking. The color of the fluorocarbon coating can be freely selected.

「Honeycomb aluminum plate processing technology」

Cold pressing: single processing time is long, and the same size specifications can be cold pressed together, which is suitable for batch processing of single specifications, with smooth surface and stable quality.

Hot pressing: single processing time is short, suitable for projects with multiple specifications of plates. Because the temperature difference changes greatly when the plate is removed, the large plate will be slightly deformed and needs cold pressing and leveling.

Vacuuming: suitable for processing special-shaped and hyperbolic plates. If the plate is too large or the stress is slightly large, it is easy to leave bubbles during vacuuming, resulting in uneven surface.

Continuous production: high production efficiency, stable products, secondary edge sealing is required, suitable for large-scale flat plate production.

「Construction process」

① Wall honeycomb panel construction

Measurement and layout → Base cleaning → keel installation line → (base and keel) drilling (drilling) holes → Install expansion bolts → Fix base keel → Drill screw holes → Install anti-slip buckles → Install honeycomb panels → Apply glue → Add seals → Acceptance

② Ceiling honeycomb panel installation

Measure the pull line → Install the hanger → Install L30*2 galvanized base angle steel keel → Install honeycomb panel special connection accessories → Install honeycomb panels → Clean the surface → Sub-item inspection and acceptance

02.Application of honeycomb panels

Honeycomb aluminum panels are widely used in aviation manufacturing, building curtain walls, exterior wall panels, interior ceiling decoration, commercial transport vehicles and container truck bodies, buses, trains, subways and rail transit vehicles, etc. In addition, honeycomb aluminum panel panels have a variety of choices, such as solid wood, aluminum plates, natural stones, stainless steel plates, etc. can all be made into honeycomb panels, and material selection is convenient.

Application of building curtain wall

Due to its excellent performance, honeycomb aluminum panels can be used to design large, straight and exquisite walls with great flexibility in size and shape.

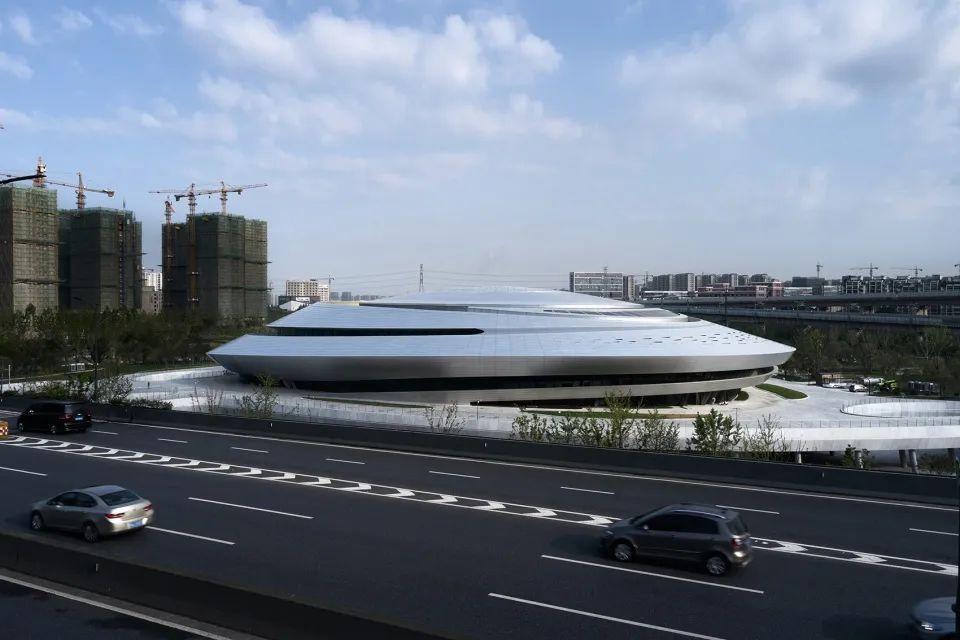

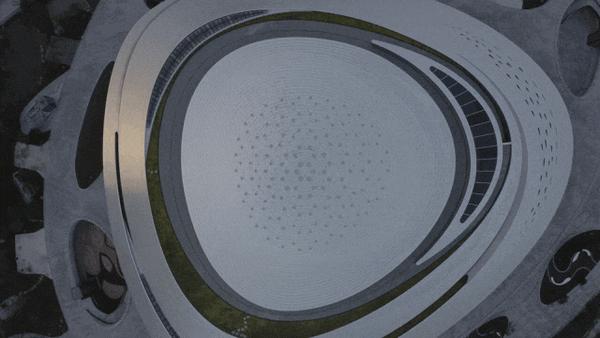

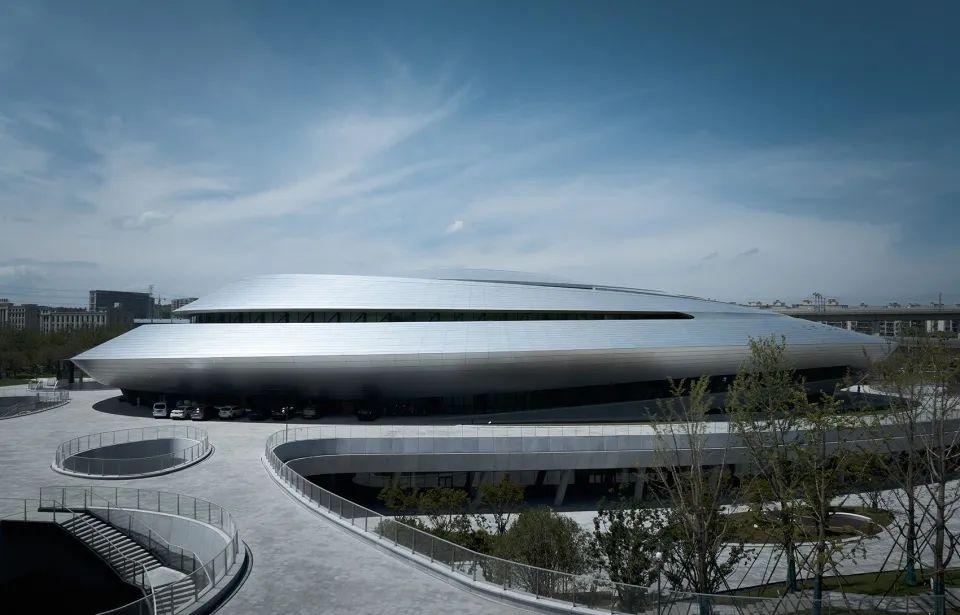

China Hangzhou E-sports Center

Design: Zhongnan Architectural Design Institute Co., Ltd.

The building’s surface is covered with hyperbolic anodized honeycomb aluminum panels. Against the backdrop of the sky, the facade slightly reflects the surrounding environment. As the angles of the curved surface change and the viewpoints of the crowd move, the “weight” of the building is gradually reduced.

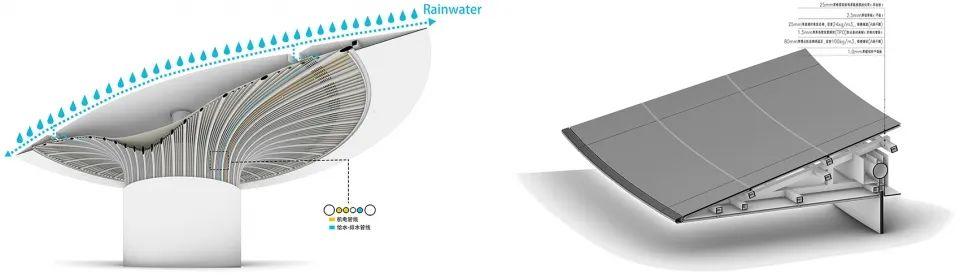

China Maritime Museum Sail Curtain Wall

Design Unit: Shanghai Architectural Design Institute Co., Ltd.

Co-design: German GMP Architects

The central sail roof of the museum’s main building adopts a hyperbolic honeycomb aluminum panel curtain wall, with an overall height of about 58m and a metal curtain wall area of about 15,000㎡.

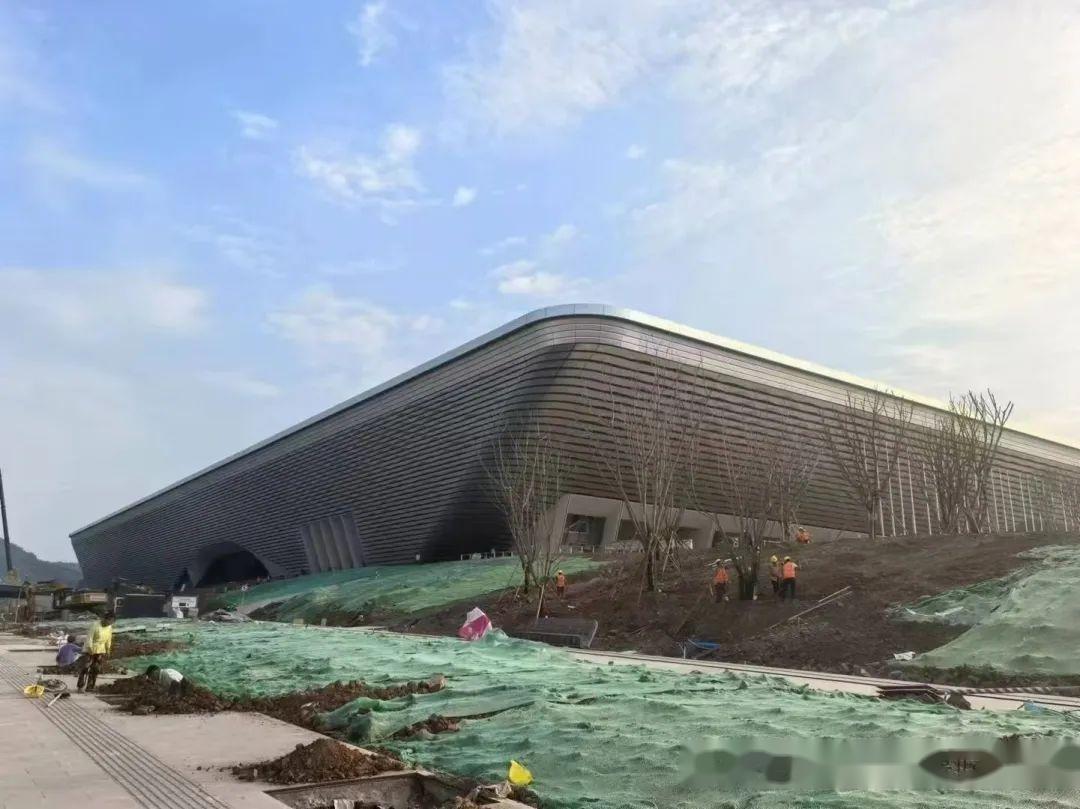

Zhiye Library, East New District, Chengdu

Design: China Architecture Southwest Design Institute Co., Ltd.

Silver-gray honeycomb aluminum panels are used for the building roof and eaves to ensure the flatness of the finished product. The degree of completion of the details of the eaves has a great impact on the overall effect. After many rounds of deliberation and research, the final arc-shaped custom profile with a radius of 25mm was selected to use the special shape of the arc surface to reduce the visual thickness of the eaves.

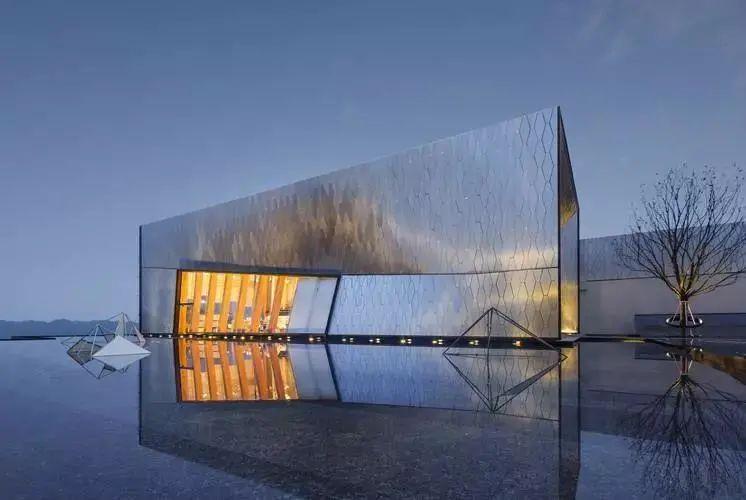

Hangzhou Greentown Jianfa Qinyuan Residential Project

Architectural Design: GLA Architectural Design

The building facade uses honeycomb aluminum panels and dark European gray glass, using the delicate aluminum profiles to outline the transparent geometric shapes of honeycomb aluminum panels and large low-e glass.

Products

-

6061 Aluminum Coil

Rated 0 out of 5

6061 Aluminum Coil

Rated 0 out of 5 -

5052 Aluminum Coil

Rated 0 out of 5

5052 Aluminum Coil

Rated 0 out of 5 -

3105 Aluminum Coil

Rated 0 out of 5

3105 Aluminum Coil

Rated 0 out of 5