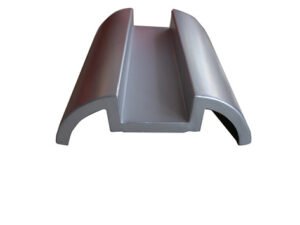

Imitation wood grain aluminum veneer

Imitation wood grain aluminum panels are a modern building decoration material made primarily of high-grade aluminum alloy. Through a transfer printing process, the texture and color of wood are imprinted onto the aluminum surface. Here’s a detailed introduction:

Product Features

-

Elegant Appearance: Rich wood grain patterns with clear and refined textures, capable of meeting various architectural design styles.

-

Environmentally Friendly: Aluminum is 100% recyclable and eco-friendly. It replaces traditional wood decoration materials, is odorless, non-polluting, and helps conserve forest resources.

-

Lightweight: The panels are lightweight yet strong, with 3.0mm thick aluminum sheets weighing only 8kg per square meter and tensile strength ranging from 100-280 N/mm².

-

Superior Physical Properties: Excellent fire resistance, corrosion resistance, moisture resistance, and hardness. The surface coating, made from Kynar-500 or Hylur 500-based PVDF fluorocarbon paint, ensures the panels remain colorfast for up to 50 years.

-

High Malleability: Can be shaped into various complex geometries (e.g., flat, curved, or spherical surfaces). The backside can also be filled with insulation, soundproofing, or sound-absorbing materials for enhanced functionality.

-

Quick Installation: Prefabricated in the factory, these panels require no on-site cutting and can be easily mounted onto a framework.

-

Easy Maintenance: Resistant to dirt and stains, making them simple to clean and maintain. The non-stick fluorocarbon coating on the surface enhances self-cleaning properties.

-

Long Service Life: Suitable for both indoor and outdoor use, they can withstand environmental changes and maintain their appearance for 10-15 years without discoloration or deformation.

Manufacturing Process

There are three main methods for producing imitation wood grain aluminum panels:

-

Heat Transfer: Using a heat transfer film, the wood grain pattern is imprinted onto the aluminum surface in a single heating process. The aluminum surface is pre-treated with powder coating or electrophoresis. This method is suitable for flat or regularly curved surfaces.

-

Water Decal Transfer: A process where patterns or text from a transfer paper are completely transferred onto the aluminum surface. This method is ideal for decorative purposes and is widely used for complex shapes.

-

Water Dip Transfer: A process that uses water pressure to transfer wood grain patterns onto the aluminum surface. It is suitable for irregularly shaped panels and allows for full-surface wood grain transfer.

Application Areas

-

Building Exteriors: Widely used for decorating the exteriors of commercial buildings, hotels, exhibition halls, hospitals, and office buildings, creating a warm and comfortable appearance.

-

Interior Decoration: Ideal for interior walls, ceilings, and partitions in residential homes, villas, hotel lobbies, and conference rooms, creating a natural and elegant atmosphere.

-

Furniture Decoration: Can be used for the surfaces of wardrobe doors, cabinet doors, and desk panels, offering a lightweight, durable, and easy-to-clean alternative to solid wood furniture.

-

Landscape Architecture: Used in parks, squares, and scenic spots for pavilions, railings, handrails, sculptures, landscape walls, and signage, enhancing artistic appeal and visual interest.

-

Special Applications: Suitable for column cladding, billboards, and other unique decorative needs, leveraging the realistic wood grain effect and excellent performance of the panels.