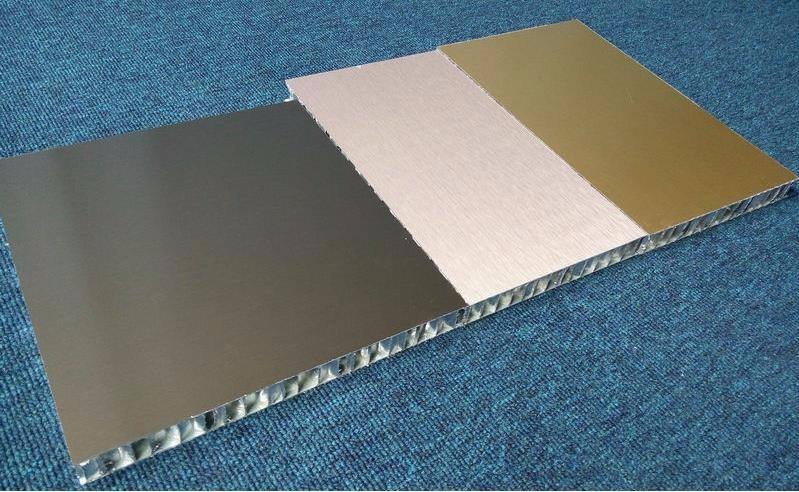

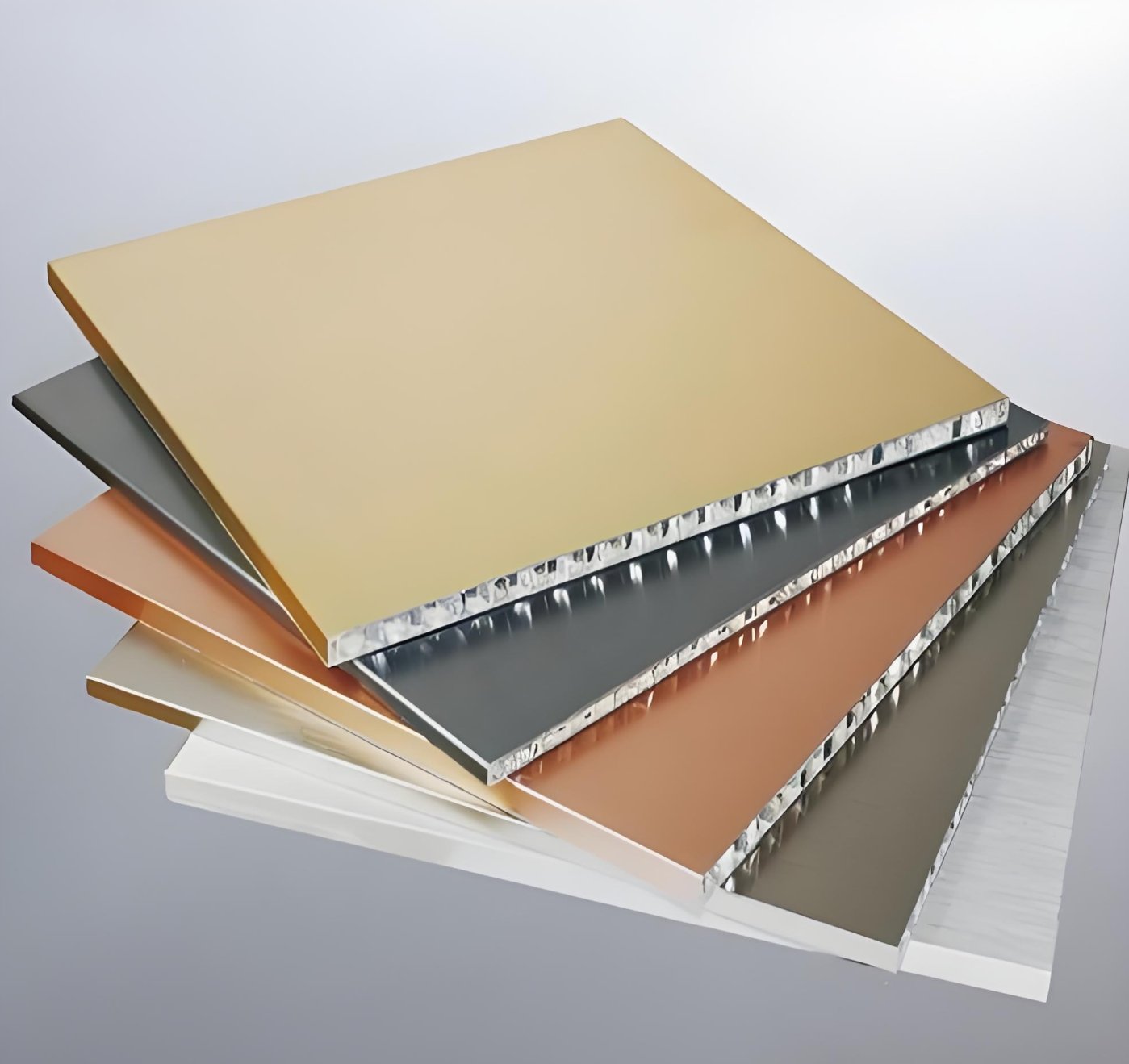

The all-aluminum furniture industry originated with aluminum honeycomb panels. However, with the introduction of joint panels, PVC panels, and welded whole panels by manufacturers, aluminum honeycomb panels experienced a period of eclipse.

Why, after being on the market for years, have “glue-free aluminum honeycomb panels” only recently gained popularity in the all-aluminum furniture industry? “Glue-free aluminum honeycomb panels” refer to panels bonded with flow films (also known as hot-melt film aluminum honeycomb panels or high-molecular film aluminum honeycomb panels), not traditional adhesives. The term “glue-free” means the absence of liquid glue, not the absence of any bonding agent. For terminal all-aluminum furniture processing plants and dealers, “glue-free aluminum honeycomb panels” serve as a strong environmental and sales advantage. However, the term “glue-free” can be misleading. If someone complains about false advertising by all-aluminum furniture manufacturers, it could lead to penalties, as seen in past cases.

Let’s delve into the journey of “glue-free honeycomb panels” (also called flow film honeycomb panels or high-molecular honeycomb panels) within the all-aluminum furniture industry.

In 2018, high-molecular aluminum honeycomb panels using flow films as the bonding material emerged in the all-aluminum furniture industry. Longshide All-Aluminum Furniture General Manager Ji De was among the first to experiment with this material, marking the initial concept of “glue-free honeycomb panels.” At that time, the all-aluminum furniture market was dominated by joint panels, leaving little room for aluminum honeycomb panels, let alone flow film honeycomb panels.

In 2020, influenced by the widespread use of aluminum honeycomb panels in ceiling systems and the impact of flow film honeycomb panels, several all-aluminum furniture enterprises, such as HANKO and Annecy, re-entered this field. After years of hard work, these companies have persisted in the flow film honeycomb panel sector despite various challenges.

In 2021, aluminum honeycomb panels regained popularity, with multiple versions, structures, and combinations emerging. Flow film honeycomb panels also found extensive applications in the integrated ceiling system domain. Numerous integrated ceiling enterprises invested in this area, leveraging hot-press machines, bread ovens, and large-scale continuous automated production lines. The integrated ceiling industry quickly popularized the concept of glue-free honeycomb panels. However, due to the high demand for “light, thin, and rigid” characteristics in integrated ceiling honeycomb panels, flow film honeycomb panels, while meeting the “light” and “thin” requirements, fell short in “rigidity” and were relatively expensive, eventually losing market competitiveness.

In 2022, a new material emerged in the all-aluminum furniture industry: glue-free aluminum honeycomb panels, also known as “hot-melt film aluminum honeycomb panels,” “high-molecular film aluminum honeycomb panels,” or “hot-melt adhesive film aluminum honeycomb panels.” HANKO once again spearheaded the promotion of “glue-free aluminum honeycomb panels” in the all-aluminum furniture industry. Built on its large-scale continuous automated production line and ultra-scratch-resistant decorative surfaces, the company aggressively marketed high-molecular film aluminum honeycomb panels through various channels, reinvigorating the concept of “glue-free aluminum honeycomb panels.” However, despite the resurgence of aluminum honeycomb panels, the all-aluminum furniture industry was still in the early stages of development for aluminum honeycomb panels, with various constraints limiting the growth of “glue-free honeycomb panels,” which gradually faded from the spotlight.

At the beginning of 2023, Cabinet Brother attempted to promote “glue-free aluminum honeycomb panels” within the all-aluminum furniture industry. Nevertheless, the high cost and surface treatment challenges of glue-free aluminum honeycomb panels at that time hindered their widespread adoption.

From the beginning to mid-2024, Filumena, under the Yilei brand, continued to champion “glue-free honeycomb panels” in the all-aluminum furniture industry, participating in numerous exhibitions. With pricing and surface treatment technologies nearing those of traditional adhesive-based honeycomb panels, Filumena inspired more enterprises to enter the glue-free aluminum honeycomb panel sector.

By the end of 2024, after years of accumulation and against the backdrop of severe market competition in traditional cold adhesive aluminum honeycomb panels, “glue-free aluminum honeycomb panels” finally gained significant traction in the all-aluminum furniture industry. Numerous all-aluminum furniture enterprises recognized the potential of this “novel product” and increased their investment. Many companies followed suit, launching their own “glue-free aluminum honeycomb panel” products through various means.

The production process for glue-free aluminum honeycomb panels is not complex. As technology has advanced, processes have been refined, and production scale has expanded, the cost of glue-free aluminum honeycomb panels has approached that of traditional cold adhesive aluminum honeycomb panels. The main differences lie in the higher investment and energy consumption in the pressing process and the material requirements for glue-free panels, which small-scale aluminum honeycomb panel factories often cannot meet. They usually only enrich the decorative surface process. These technical and investment barriers have elevated the market entry threshold for glue-free aluminum honeycomb panels, creating market differentiation compared to cold adhesive aluminum honeycomb panels. However, all-aluminum furniture manufacturers should exercise caution when using the term “glue-free aluminum honeycomb panels.”